RiceBead RFID tag is now the most advanced, smallest, anti-metal, UHF RFID tag. Together with BoundTable powered by BoundField Technology, it provides the best solution for routine traceability of instrument reprocessing in Sterile Supply Department (CSD) and instruments counting in operation room to comply with gs1 and UDI standards and regulations. It could also be applied to asset management of other metal tools in various scenarios.

Introduction

RiceBead RFID tag is specially designed for single instrument tracking, and a great step foward than QR codes. Thanks to the superb processing technology from Japan, it realizes the ultra-high frequency near-field resonance circuit in the tiny size of rice bead by micro-carving technology.

It ensures the reading distance of this tiny tag is the same as the tags with 10 times larger size (e.g. standard RFID near-field tags Impinj J41, J51, Alien9613, etc.)

Comparison to QR Codes

RFID tags have a lot advantages comparing to QR codes:

1. Batch Reading. Hundreds of instruments with RFID tags can be read and identified in few seconds, while it'll take you 10 - 15mins to scan the QR codes one by one.

2. Blind Operation. Instruments can be read at any positions or place, but for QR coded instruments, QR code must be found and place the code in front of the scanner, and the QR is tiny that you may need to adjust the distance and positions a few times to get a successful reading.

BoundTable powered by BoundField Technology provides the most accurate reading area of RiceBead RFID tags to ensure no interference with other RFID readers even if two BoundTables are placed side by side, preventing reading instruments on other readers or passing by.

How Could It Be Applied to Existing Instruments?

For existing instruments in your CSSD, a special medical grade Epoxy Resin glue will be provided with a special tool to glue the RiceBead tags to the instruments. The glue is specially designed to withstand the ultrasonic washing, chemical soaking, washer disinfection, dryers, autoclaving, VH2O2 (plasma) sterilizers and all other routine reprocessing means. Color of the glue can be customized to differentiate instruments from different departments, or different facilities.

Will It Influence Sergons?

In case surgeons are very senstive to raised RFID tags from instruments, it is recommended to laser cut a tiny pit 5x2.5x1.5mm (1.5mm deep) on surface of instruments. RiceBead falls into the pit and the surface would be smooth. And smooth surface is good for cleaning and disinfection.

How Long Does It Stay on Instruments?

With a special designed Epoxy Resin for glueing, according to test results in a contract CSSD, raised RiceBead tags glued to instruments stay for over 1200 cycles of routine reprocessing methods: ultrasonic cleaning, chemcial soaking and washing, high temperature drying and high temperature autoclaving. Contact us for detailed test reports.

I'm from Hospital

If you would like to apply RiceBead and BoundField RFID technology to your traceabilty process, you may contact us for our local service provider to provice you a total solution.

I'm A Tracking Software Manufacturer

We're open to work with all tracking system manufacturers to build connectivity to our BoundTable with APIs, and therefore provide access to reading resutls of RiceBead tagged instruments. If your system is already capable to provide tracking to single instruments, you may contact us for how to provide a better tracking experience to your customers.

BoundTag RFID labels that withstand autoclaving are also provided for tracking a package for easy stocktaking at various stages or reprocessing and delivery.

Portable RFID Printer with open API is also provided for printing, reading and writing of BoundTags.

I'm A Surgical Instruments Manufacturer

If you're planning to get your instruments in compliance with UDI and gs1 standards with build-in RFID tags instead of QR codes, we're ready to provide you with a total solution to build RiceBead tags inside your instruments to provide the best inventory, logistics and reprocessing traceability experience to your end users. All you need to do is to prepare a 5x2.5x1.5mm (1.5mm deep) pit on your instruments and the finish will be smooth and nice, and won't influence handling of surgeons.

Instruments with built-in RFID tags are the future. Don't wait for the future to come, be the future!

Features

1 | World's smallest UHF RFID tag. | 2 | Withstands steam sterilization, detergent and disinfecting chemicals, ultrasonic washing, etc. | 3 | Perfect reading performance regardless the material, size of instrument, also location of the RFID tag. |

Advantages

Item | RiceBeads | UHF RFID Metal Tag (Applicable to both metal & non-metal objects) | UHF RFID Metal Tag (Only for metal objects) |

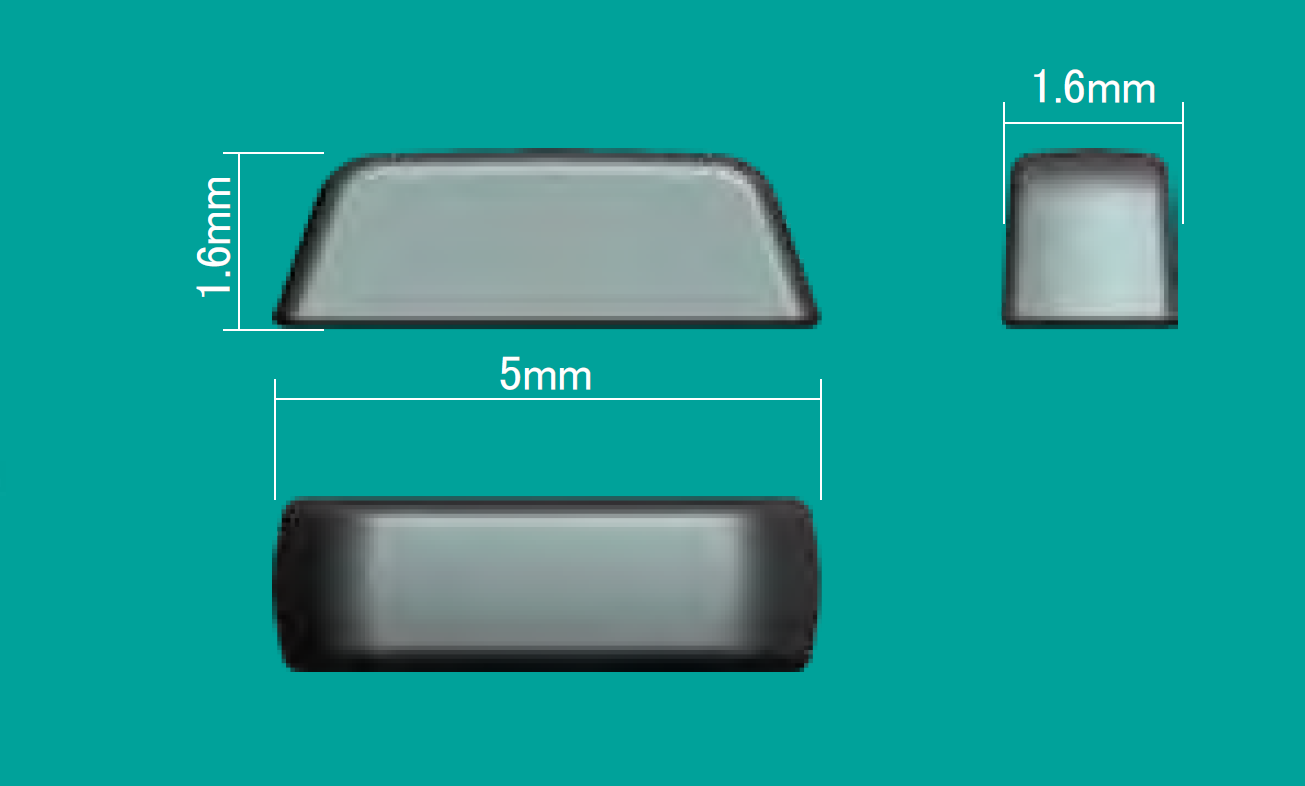

Size (mm) | 5x1.6x1.6 | 100 times of RiceBeads’ size | 10 times of RiceBeads’ size |

Thickness (mm) | 1.6 | >5 | 1~5 |

Reading performance is related to the size of object? | No | No | Yes |

Reading performance is related to the location of tag? | No | No | Yes |

Reading performance is related to the material of object? | No | No | Yes |

Suitable for non-metallic materials? | Yes | Yes | No |